Difference between revisions of "Laser Engraving Machine"

Thanos.Husk (Talk | contribs) (→Material Information) |

(syntax correction and inkscape link fix) |

||

| (14 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | The model of the Laser Engraving Machine located in Hackerspace.gr | + | The model of the Laser Engraving Machine located in Hackerspace.gr is HQ-3020B. |

It is capable of cutting, engraving, and marking a number of different materials quickly and accurately when driven from CAD software such as CorelDraw and Inkscape. | It is capable of cutting, engraving, and marking a number of different materials quickly and accurately when driven from CAD software such as CorelDraw and Inkscape. | ||

| − | The bed size is 35cm x 25cm. | + | The bed size is 35cm x 25cm. |

== Maintenance == | == Maintenance == | ||

| − | + | The machine's mirrors and lens should be cleaned lightly before every startup and thoroughly once a month as instructed in this [https://k40.se/k40-laser-lens-mirror/cleaning/ guide]. | |

| − | + | Every 6 months the cooling liquid needs to be drained and replaced by new. The liquid is a mix of distilled water and an anti-algae solution. With every cooling liquid replacement it is also advised to perform a cleaning of the cooling system following this [https://k40.se/k40-laser-watercooling/cleaning/ guide] | |

| Line 81: | Line 81: | ||

|- | |- | ||

|Acrylic (transparent) | |Acrylic (transparent) | ||

| − | | | + | |Non dependent |

|Engrave | |Engrave | ||

| − | | | + | |12 |

|20 | |20 | ||

|1 | |1 | ||

| Line 92: | Line 92: | ||

|40 | |40 | ||

|10 | |10 | ||

| + | |2 | ||

| + | |- | ||

| + | |Acrylic (transparent) | ||

| + | |Non dependent | ||

| + | |Raster Engrave | ||

| + | |12 | ||

| + | |200 | ||

|1 | |1 | ||

|- | |- | ||

| Line 119: | Line 126: | ||

|Cut (adhesive on) | |Cut (adhesive on) | ||

|7 | |7 | ||

| + | |10 | ||

| + | |1 | ||

| + | |- | ||

| + | |Standers foam | ||

| + | |2 | ||

| + | |Cut (adhesive on) | ||

| + | |13 | ||

|10 | |10 | ||

|1 | |1 | ||

| Line 129: | Line 143: | ||

'''Download:''' | '''Download:''' | ||

| − | > Inkscape [https://inkscape.org/release | + | > Inkscape [https://inkscape.org/release/] |

> K40 Whisperer [https://www.scorchworks.com/K40whisperer/k40whisperer.html] | > K40 Whisperer [https://www.scorchworks.com/K40whisperer/k40whisperer.html] | ||

| Line 612: | Line 626: | ||

| + | |||

| + | |||

| + | > Last cleanup: mirrors - '''28/09/22''', tube - '''XX/XX/22''' | ||

== Useful links == | == Useful links == | ||

| Line 619: | Line 636: | ||

> obrary [https://obrary.com/collections/open-designs] | > obrary [https://obrary.com/collections/open-designs] | ||

| + | > makercase [https://www.makercase.com/#/] | ||

| + | |||

| + | > geargen [https://geargenerator.com/] | ||

== Projects == | == Projects == | ||

Latest revision as of 22:02, 16 February 2024

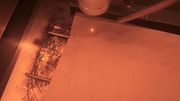

The model of the Laser Engraving Machine located in Hackerspace.gr is HQ-3020B. It is capable of cutting, engraving, and marking a number of different materials quickly and accurately when driven from CAD software such as CorelDraw and Inkscape. The bed size is 35cm x 25cm.

Maintenance

The machine's mirrors and lens should be cleaned lightly before every startup and thoroughly once a month as instructed in this guide.

Every 6 months the cooling liquid needs to be drained and replaced by new. The liquid is a mix of distilled water and an anti-algae solution. With every cooling liquid replacement it is also advised to perform a cleaning of the cooling system following this guide

Material Information

Materials that can and cannot be laser-cut [1]

| Material | Thickness (mm) | Operation | Power | Feed (mm/s) | Passes |

|---|---|---|---|---|---|

| Flexoid Oil Resistant Jointing sheet [2][3] | 0.5 | Cut | 17 | 10 | 1 |

| Flexoid Oil Resistant Jointing sheet [4][5] | 0.8 | Cut | 20 | 10 | 1 |

| TEMAFAST ECONOMY [6] | 1 | Cut | 40 | 10 | 5 |

| Plywood | 3 | Cut | 30 | 10 | 2 |

| Plywood | 4 | Cut | 45 | 10 | 2 |

| Plywood | Non dependent | Engrave | 20 | 20 | 2 |

| White glossy vinyl | 0.24 | Cut | 7 | 20 | 1 |

| Black matte vinyl | 0.24 | Cut | 7 | 20 | 1 |

| Acrylic (transparent) | Non dependent | Engrave | 12 | 20 | 1 |

| Acrylic (transparent) | 3 | Cut | 40 | 10 | 2 |

| Acrylic (transparent) | Non dependent | Raster Engrave | 12 | 200 | 1 |

| Leather (brown) | Non dependent | Engrave | 10 | 20 | 2 |

| MDF | 2 | Cut | 70 | 10 | 1 |

| MDF | 2 | Raster Engrave | 15 | 200 | 1 |

| Reflective tape (PVC/red) | 0.36 | Cut (adhesive on) | 7 | 10 | 1 |

| Standers foam | 2 | Cut (adhesive on) | 13 | 10 | 1 |

How to use it:

Download:

> Inkscape [7]

> K40 Whisperer [8]

To create your file:

> Open Inkscape

> Draw your design with lines

> Make colors in RGB (Blue to engrave, red to cut)

> Select correct Document Properties:

- UNITS must be all in MM

- RESIZE page to content

> Save as .svg file.

To cut your file:

> Connect computer and machine with USB cable

> Switch on the machine:

- Switch power on

- Switch light on

- Plug-in air - compressor

In K40 Whisperer:

( > Open K40 Whisperer )

> Initialize laser-cutter

> Open design file

> Adjust starting point and speed in K40 Whisperer

On the machine:

> Place your material inside (it must be no bigger than A4)

> Adjust power on machine

> Make test

> First engrave (BLUE) and then (CUT) by clicking "Vector Engrave" and "Vector Cut" in "K40 Whisperer".

Make sure temperature does not exceed 30 °C

> Switch off machine

> Clean up gently with vacuum cleaner

> Last cleanup: mirrors - 28/09/22, tube - XX/XX/22

Useful links

> boxes.py [9]

> obrary [10]

> makercase [11]

> geargen [12]

Projects

> what is cosmos / τι είναι κόσμος

This text contains information copied or inspired from http://atxhackerspace.org .